Author: Dave Marshall-George, UK & IE Sales Director, Condair Ltd

Desiccant vs condensing dehumidifiers

There are two main types of commercial dehumidifier – condensing and desiccant. They both lower humidity but do so in quite different ways, which frequently determines when you should use one instead of the other.

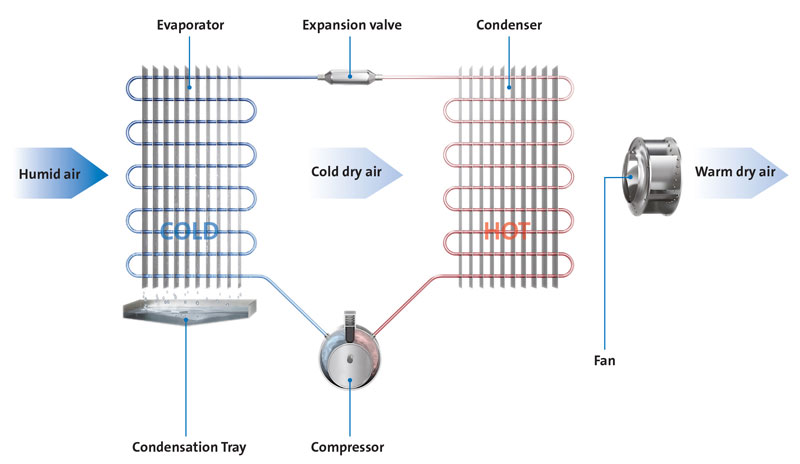

A condensing dehumidifier operates using the basic principle of creating a cold surface upon which moisture from the air will condense. It incorporates the type of refrigeration circuit that you would find in a fridge or AC unit. Air is drawn into the dehumidifier with a fan and meets the cold coil evaporator element of the fridge circuit. Its temperature is reduced below dew point, causing condensation to form on the coil, from where it drips to drain or into a water tank for disposal. The cold air is then heated with the condenser part of the fridge circuit before being returned to the room, drier and slightly warmer than it entered the dehumidifier.

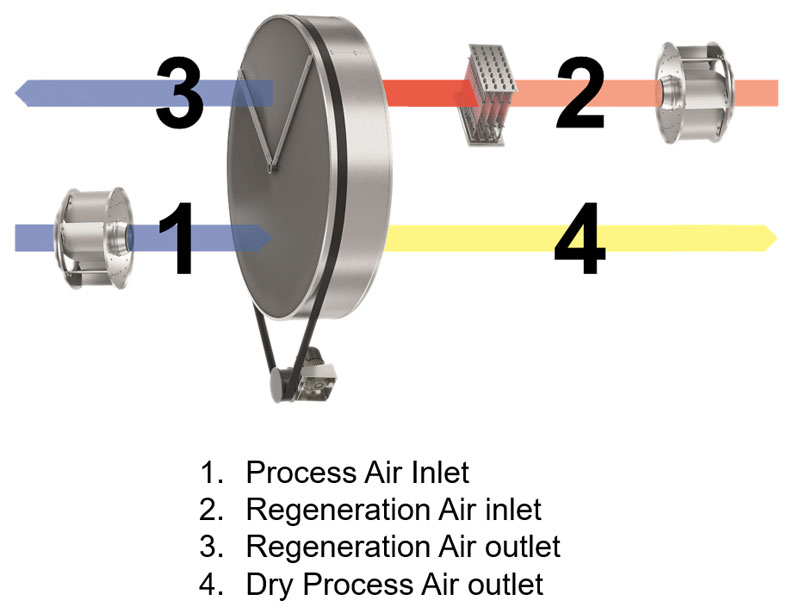

A desiccant dehumidifier operates using the adsorption properties of a rotating desiccant wheel, a bit like a sponge literally soaking up moisture directly from the air. Air is drawn into the dehumidifier and passes through a slowly revolving desiccant wheel. The desiccant absorbs moisture and the dried air is returned to the room. In order to allow the desiccant wheel to indefinitely absorb moisture, the wheel passes through a regeneration area, where it is heated by a secondary hot airstream. A heater, frequently electric, heats this secondary airstream to around 120°C before passing it through the wheel. The hot air absorbs the moisture from the desiccant and is then vented externally.

So a desiccant dehumidifier has two airstreams – a process airstream and a regeneration airstream, which exhausts the moisture collected from the process airstream. As the freshly regenerated part of the wheel is hot, it carries some residual heat when it rotates back into the process airstream. Therefore, as well as drying the process airstream, the desiccant wheel also provides some heat.

Selection

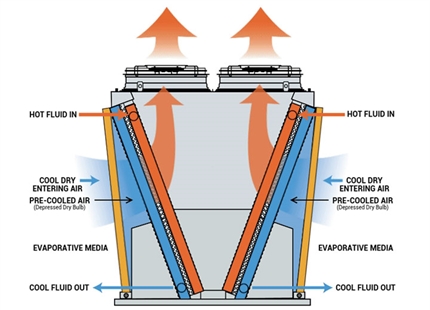

As a condensing dehumidifier relies on temperature to dry the air, the technology is most efficient when the atmosphere is warm. The warmer the room, the greater the condensation effect on the dehumidifier’s cold evaporator coil. This makes this type of technology ideal for applications like swimming pools, where the air is typically very warm and moist. Especially, as some condensing dehumidifiers can incorporate heat recovery systems, which return the heat generated from the drying process to heat the pool water.

If the atmosphere requiring dehumidification is lower than around 20°C, frequently desiccant dehumidifiers start to become a more efficient solution. Their efficiency of operation is not temperature dependent, so they perform well in both warm and cold environments. However, this flexibility comes at a cost, as they do use more energy than condensing systems, due to the heating required to regenerate the desiccant wheel. In comparison, a condensing system would typically consume 0.5-1.5kW to remove one kilo of water, while a desiccant would consume 1-3kW for the same capacity. It is possible for a desiccant dehumidifier to incorporate a gas or hot water heat exchanger, which can reduce the cost of this energy consumption.

Due to the need to vent the regeneration airflow externally, to get rid of the hot wet air coming off the desiccant wheel, desiccant dehumidifiers can also be more complicated to install. A condensing dehumidifier can dry an atmosphere with only an electrical supply and a drain. A desiccant dehumidifier will always need ducting to vent the regeneration airflow away from the area being dried.

So with the higher energy costs and the more complex installation requirements involved in desiccant dehumidification, if a project’s environmental conditions suit a condensing dehumidifier, it will normally be the most cost effective solution. However, temperature isn’t the only determining factor. Condensing dehumidifiers are very effective at maintaining an atmosphere as low as 45-50%RH. If a project calls for a humidity level below this, desiccant technology offers more powerful drying performance. A desiccant dryer can deliver extreme environmental control as low as 1%RH. This is ideal for manufacturing processes, such as lithium battery production, where very low humidity levels are needed.

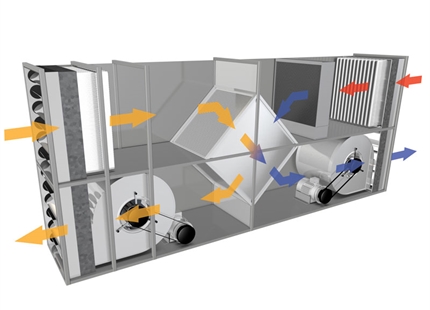

Effectively managing the heat generated during a drying project can also be a determining factor in technology selection. If close environmental control is needed in a project, this nearly always involves both temperature and humidity levels. Although the dehumidifier’s purpose is to control humidity, both technologies will heat the air they dry. This means they have an impact on the temperature management and will need to align alongside any associated heating and cooling equipment.

Again desiccant technology offers a more flexible solution for temperature management, as it is possible to fit pre- or post- modules to a desiccant dehumidifier that can additionally heat or cool the air. There is the possibility with some advanced condensing systems to incorporate remote condensers, which can exhaust the heat air away from the process air delivery. This can provide control over heat management but not to the precise levels offered by desiccant technology.

So in summary, for projects that need humidity control at 45%RH or above and at around 20°C or warmer, condensing dehumidifiers can be the most cost effective solution. Whilst applications that drop below this temperature level, even for short periods of time, or that need less than 45%RH, or advanced temperature management, desiccant dryers offer a much wider performance range.