Humidification & humidity

control in the packaging industry

A large supermarket offers over 40,000 packaged products, each competing with others to grab the eye of the consumer. It’s easy to see, from this one market alone at just one point in the supply chain, why the importance of packaging is so great. The protection, preservation and presentation of the products is crucial but, combined with the need to be innovative, competitive and environmentally aware, modern packaging producers often represent best practice in design, converting and printing. Quality and productivity are essential, and the right humidity plays an essential role in many areas of production.

Label printing

Label printing is amongst the finest quality sheet and web based printing, often in more colours including brand-related tones than regular printing, and consistency from one run to the next are essential. Tight control of register and dot density, especially in multipass work, is essential. Preventing tight edges, curl and creasing, together with electrostatic prevention, mean that humidification to 50-55%RH is typical in the sheetfed litho press hall. In web offset, similar humidity control is needed pre-press and in the press hall, to prevent tight edges and web breaks.

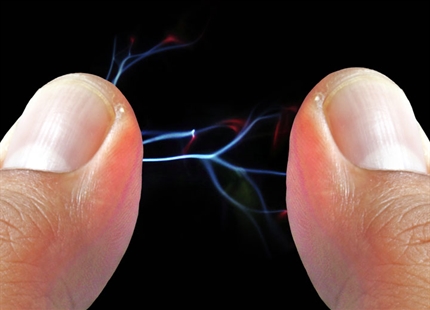

Foil

For premium products, volumes are lower and very high quality is required, often including metal foils and films applied to paper labels. For foil and film, electrostatic prevention is essential for straightforward handling and adhesion. Whilst the threshold for electrostatic control is 40-45%RH, the conditions required for printing are such that 50-55%RH is commonly maintained throughout the area.

Slitting and rewinding

The slitting and rewinding of web and narrow web label reels can be a source of electrostatic generation. Humidification to 45%RH helps prevent this.

Adhesives

Many adhesives are sensitive to ambient humidity, losing moisture to dry air. This dries the adhesive so that labels fail to stick to the substrate (commonly glass and tin cans) and cartonboard glue flaps fail to stick. Commonly, glues are in equilibrium with paper and 50-55%RH addresses the matter.

Cartonboard, card and corrugated board

Thicker papers and boards are less susceptible to curl and electrostatic problems, although not immune from them, so raw material and blanks are best stored and worked at 50-55%RH. More significant is the problem of cracking on the external face of folds in thicker papers and boards, due to loss of flexibility of dry boards. This is most obvious on printed work, where the white substrate is revealed, inevitably meaning the batch is rejected. Again, storage and converting at 50-55%RH will typically address the matter.

Embossing paper and board

Paper flexibility and strength are affected by moisture content. Embossing exposes the paper to the risk of cracking and tearing, especially in the newly created thinner areas of dry paper. Whether at the paper supplier or in production, the maintenance of 50-55%RH helps maintain optimum moisture content and counter this problem.

Film processing and printing

Packaging films are particularly susceptible to electrostatic, from extrusion, through printing to rolling. Because the films are commonly not as hygroscopic as paper and board, higher levels of humidity are needed to help disperse ‘static charges. 50-55% is typical but 60%RH is not uncommon.

Benefits of Condair humidification in the packaging industry include:

- Extensive experience in all packaging process from projects around the world

- Comprehensive product range to precisely meet production requirements

- Low energy and low maintenance humidification solutions

- High production speeds and less downtime of machinery

- Reduces electrostatic build-up and subsequent discharge

- Prevents dimensional changes to materials and problems of mis-register

- Prevents cracking along folds

- Mayr-Melnhof Packaging, France

- DS Smith Packaging, France

- Hewlett Packard, Spain

- Tetra Pak, China

- SCA Packaging, Sweden & UK

- Marinetti-Packaging, Chile

- MM Packaging, Germany

- Tralin Pak, Mongolia

- Jiffy Packaging Ltd, UK

- Collotype Labels Ltd, UK & Australia

Click here to see our packaging clients from around the world.