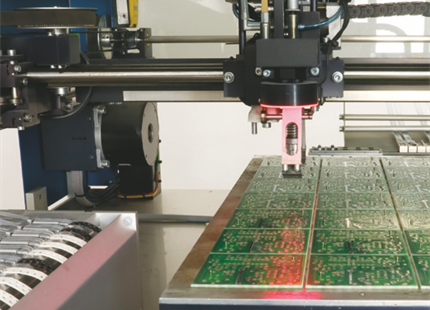

Humidity control in semiconductor & PCB manufacturing

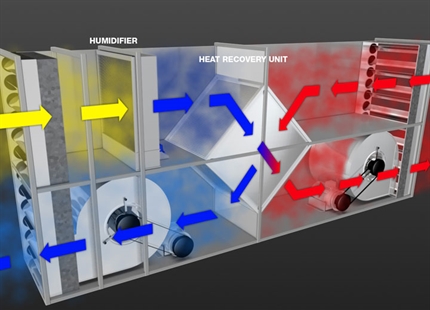

Humidity control in the production of semiconductors is used to prevent the build-up of static electricity, prevent dimensional changes from occurring on the surface of the silicon wafer and cool the manufacturing environment.

Any uncontrolled electrical static discharge that occurs during production can damage the surface of the semiconductors and significantly lower production yields. The manufacturing process generates heat and this in-turn dries the air. As dry air promotes static build-up, humidifiers are used to control the atmosphere to around 55% relative humidity (%rH). This encourages the static to naturally dissipate removing the risk of damage to the surface of the semiconductor.

However, the printed surfaces of the silicon wafer are also very sensitive to moisture. The conductive tracts on the surface can distort during manufacturing if exposed to incorrect humidity levels. Extremely close control of humidity to ±0.1°C dew point over any 40 minute period is required. Any variation greater than this and the conductive tracts will be damaged and the semiconductor ruined.

Resistive seam humidifiers such as the Condair RS can provide this precise level of control while cold water humidifiers also offer the additional benefit of evaporative cooling. This helps lower the ambient temperature during manufacturing and reduces the required cooling, saving energy and lowering costs.

Get free expert advice on humidity control in cleanroom environments

Benefits of Condair humidity control in the semi-conductor industry include:

- Humidification and dehumidification from a single supplier

- Comprehensive product range to precisely meet customers' requirements

- Extensive expertise around the world with many leading semi-conductor and PCB manufacturers

- Ability to provide innovative custom solutions for unique processes

- Low maintenance and low energy solutions for reduced on-going costs

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

Humidification & drying specialists

Free 10-point guide to cleanroom humidity control

This guide has been compiled from Condair's extensive experience across thousands of cleanroom humidity control projects.

It gives an overview of the 10 most important topics to consider when setting out on a cleanroom humidification or dehumidification project.

PODCAST: CLEANROOM HUMIDITY CONTROLLearn how to manage humidity in tightly controlled areas.

You may also be interested in...

Medical device manufacturing humidification

Office humidification

Museums, galleries, art & antiques humidification

Hammam, Caldarium and Rhassoul

In-duct evaporative cooling strategies

Home humidification

Electronics manufacturing

Paper & pulp production humidification

Packaging humidification